Construction processes

Aluminium working processes

Cutting

All available cutting tools may be used for cutting aluminium: shears, hacksaw, jig-saw, Dremel with cutting disc even blade knife for skins. Edge finishing, deburring

2024-T3 aluminium is quite brittle and all the cuts need to be worked upon to avoid cracks. Each cut or hole needs to be deburred, all burrs must be removed. Tools used for this are : metal files, bench grinder, sanding disks, sanding paper. To deburr holes we'll use a drilling bit greater than the hole, or a specific deburring tool (manual or to be mounted on a drill). Evert scratch has also of be removed from the metal's surface.

Countersinking, dimpling

To ensure having a exterior skin as smooth as possible, coutersunk rivetheads are used. To bury the rivethead in the skin two techniques are used. First coutersinking, by using a countersink drill (a drillbit larger than the hole), aluminium is removed to create the space for the rivethead. The other technique is dimpling, where the "cup" for the rivethead is formed into the skin. The latter is only usable on skins less than 0.040in deep.

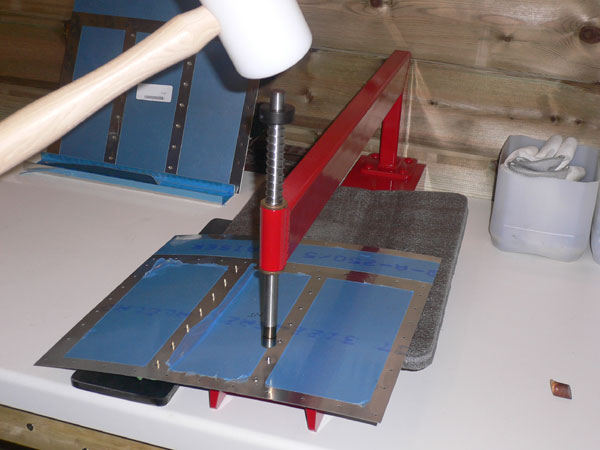

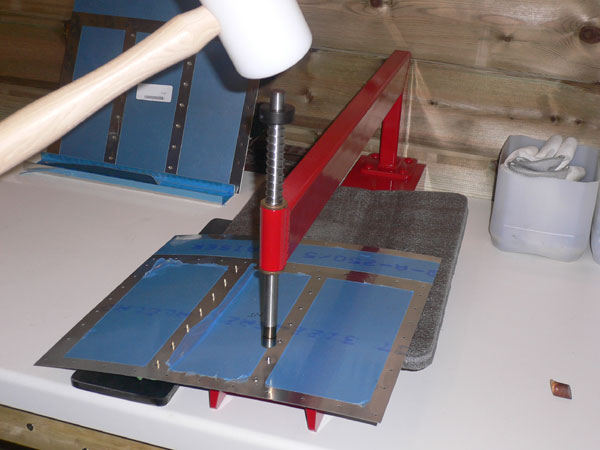

Pneumatic riveter and dimpler

C-frame : tool to dimple hole not reachable with pneumatic tool.

To protect the aluminium sheets, you trace the contours you want to remove with a soldering iron.

Fluting

During the fabrication process, the ribs become slightly out of shape. This must be corrected before assembly. Therefore, the rib flanges are fluted between two rivet holes and the flange must be made perpendicular to the web. On the picture, the rib before and after fluting and the fluting pliers.

Still to come

Riveting

Cutting

All available cutting tools may be used for cutting aluminium: shears, hacksaw, jig-saw, Dremel with cutting disc even blade knife for skins. Edge finishing, deburring

2024-T3 aluminium is quite brittle and all the cuts need to be worked upon to avoid cracks. Each cut or hole needs to be deburred, all burrs must be removed. Tools used for this are : metal files, bench grinder, sanding disks, sanding paper. To deburr holes we'll use a drilling bit greater than the hole, or a specific deburring tool (manual or to be mounted on a drill). Evert scratch has also of be removed from the metal's surface.

Countersinking, dimpling

To ensure having a exterior skin as smooth as possible, coutersunk rivetheads are used. To bury the rivethead in the skin two techniques are used. First coutersinking, by using a countersink drill (a drillbit larger than the hole), aluminium is removed to create the space for the rivethead. The other technique is dimpling, where the "cup" for the rivethead is formed into the skin. The latter is only usable on skins less than 0.040in deep.

Pneumatic riveter and dimpler

C-frame : tool to dimple hole not reachable with pneumatic tool.

To protect the aluminium sheets, you trace the contours you want to remove with a soldering iron.

Fluting

During the fabrication process, the ribs become slightly out of shape. This must be corrected before assembly. Therefore, the rib flanges are fluted between two rivet holes and the flange must be made perpendicular to the web. On the picture, the rib before and after fluting and the fluting pliers.

Still to come

Riveting

| Naviguer à travers les articles | |

First visit by GSAC

First visit by GSAC

|

Aicraft wiring

|

|

|